Click here for consultation

Engineering Group

ttsm

TTSM Engineering Group, with 30 years of experience approved by the Ministry of Energy, Petrochemical, Steel, Electrical, Automotive, and Construction Industries in the production and supply of various industrial coatings, relying on technical knowledge and an international research and development department, is ready to provide the best implementation solutions in this field.

Follow us on social media.

Faster access

Contact Us

All material and intellectual property rights of this website belong to tTSM Engineering Group.

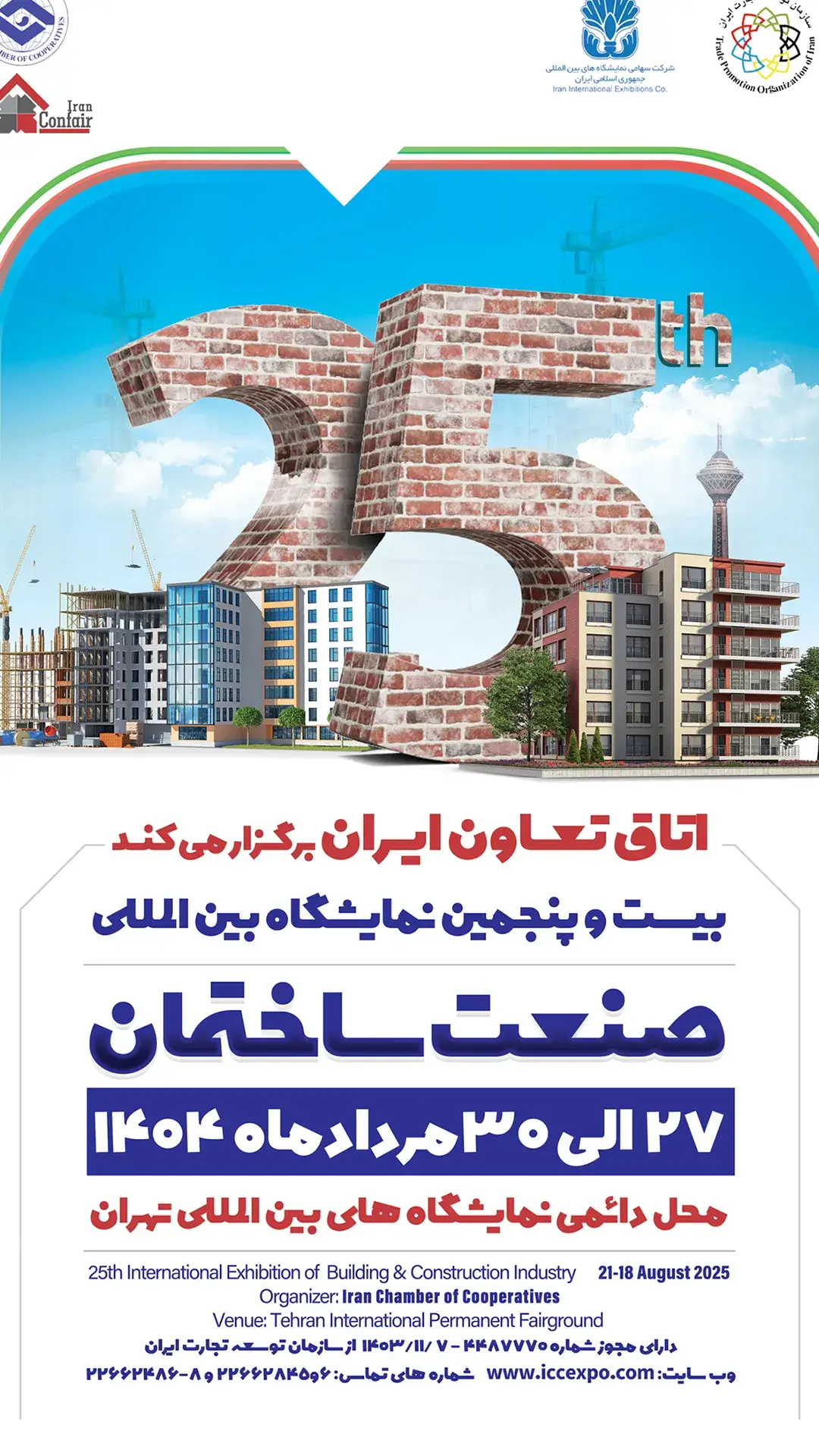

TTSM at the 25th International...

TTSM is proud to announce its participation in the 25th International Paint, Resin, Coatings, Composites & Electroplating Industry Exhibition (IPCC 2025), which will be held from December 3–6, 2025 (Azar 12–15, 1404) at the Tehran International Permanent Fairground. 📍 Booth Location: Hall 38 – Tehran International Exhibition Center At IPCC 2025, TTSM will showcase its latest innovations and high-performance solutions in: Industrial paints and resins Protective and anti-corrosion coatings Advanced composite materials Modern electroplating and surface technologies 🌐 Innovation and Quality for a Sustainable Industry With a focus on research, technology, and sustainability, TTSM continues to deliver advanced coating and surface solutions for industrial applications.We warmly invite all industry professionals and visitors to meet our team and explore our latest developments at Hall 38. 🔗 Visit our official website for more information: www.TTSM.co

۱۱ آبان ۱۴۰۴

Participation of Tala Tejarat ...

Participation of Tala Tejarat Sazeh Mahan in the 25th Tehran International Building Industry Exhibition 2025 Tala Tejarat Sazeh Mahan is proud to announce its participation in the 25th Tehran International Building Industry Exhibition 2025, which will be held from August 18 to 21, 2025 at the Tehran International Permanent Fairground. Recognized as the largest specialized event in the construction sector in Iran, this exhibition serves as a premier platform for showcasing the latest innovations, technologies, and building products. During the event, Tala Tejarat Sazeh Mahan will present its latest products and innovative solutions to visitors, engineers, architects, investors, and industry professionals. The company’s booth will offer a unique opportunity for business networking, knowledge exchange, and exploring new cooperation opportunities in the construction industry. 📍 Location: Tehran International Permanent Fairground – Hall 40 – Booth 4028📅 Date: August 18–21, 2025⏰ Visiting Hours: 9:00 AM – 4:00 PM With the continuous growth of the construction industry and the adoption of cutting-edge technologies, the Tehran International Building Industry Exhibition 2025 is an exceptional opportunity for staying up to date, discovering industry trends, and building valuable partnerships for the future.

۲۲ مرداد ۱۴۰۴

7th Exhibition of the Export C...

IRAN EXPO 2025 – The 7th Export Capabilities Exhibition of the Islamic Republic of Iran Introduction to IRAN EXPO 2025 The 7th Export Capabilities Exhibition of the Islamic Republic of Iran (IRAN EXPO 2025) will be held as the largest export-oriented event in the country from April 27 to May 1, 2025, at the Tehran International Exhibition Center. Purpose and Vision With the participation of more than 800 leading Iranian exporters and the attendance of over 1,000 foreign traders and businesspeople from across the globe, this international event provides a powerful platform to showcase Iran’s non-oil export products and to strengthen international business collaborations. TTSM.co Participation Tala Tejarat Sazeh Mahan (TTSM.co) is proud to participate in this prestigious exhibition. As one of the active players in the field of international trade and export, TTSM.co will present its specialized products and services to both domestic and international visitors. This participation creates a unique opportunity to expand our international network and establish new partnerships. Why IRAN EXPO 2025 Matters Strong E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness): By sharing real production experience, industry expertise, and proven collaborations with international partners, credibility and trust are enhanced. Information Gain: Valuable data such as the number of participants, types of products, and successful collaborations adds depth and uniqueness to the content. AI & Answer Engine Optimization: Structured Q&A content, contact details, links to TTSM.co, and the use of Schema markup improve visibility in AI-powered search results and Google SGE. Mobile-Friendly & Speed Optimized: A responsive design and fast page load ensure a seamless mobile user experience. Contextual Linking: Internal links to relevant TTSM.co pages (About Us, Contact) and external credible sources boost SEO authority. Contact and More Information For detailed information about TTSM.co’s participation in IRAN EXPO 2025, product showcases, and partnership opportunities, please visit TTSM.co or use the contact form to get in touch with our team.

۳۰ فروردین ۱۴۰۴

Holding Paint-resin exhibition

H1: International Exhibition of Paint, Resin, Industrial Coatings, Composites & Electroplating Industry Introduction The International Exhibition of Paint, Resin, Industrial Coatings, Composites, and Electroplating is recognized today as the most important scientific-commercial annual event in Iran. This exhibition provides a unique opportunity for manufacturers, industrial players, researchers, and investors to showcase their latest achievements, technologies, and products. With over 30 years of expertise, TTSM Engineering Group is one of the pioneers in the coatings industry. Participation in this event is not only a chance to highlight domestic capabilities but also a strategic step towards entering global markets. H2: Importance of the Paint & Coatings Exhibition Creates business and export opportunities Showcases innovative technologies such as nano coatings and industrial adhesives Reduces reliance on imported raw materials (only 20% imported) Enhances scientific and research-based growth of Iran’s coating industry H2: Industries Covered by the Exhibition H3: Core Industries Industrial coatings Paints and resins Electroplating (nickel, chrome, metals, plastics, anodizing, wastewater treatment, etc.) Composites and composite parts Specialized paints (construction, industrial, automotive, marine, fire-retardant, decorative, etc.) H3: Equipment & Services Paint and coating production machinery Laboratory and inspection equipment Chemical packaging and containers Safety and recycling equipment Engineering consulting and contracting services H2: TTSM’s Role in Iran’s Coating Industry TTSM Engineering Group, with over three decades of experience, is a trusted supplier of industrial coatings, paints, resins, and related equipment. Collaborating with key sectors such as petrochemicals, power plants, steel, automotive, and construction, TTSM has played a significant role in the advancement of Iran’s coating industry. H2: Why Participate in the Paint & Coatings Exhibition? Networking and direct interaction with customers and suppliers Showcasing industrial innovations and localized technologies Finding trade partners for export opportunities Gaining knowledge from international experts and specialists FAQ (Frequently Asked Questions) When does the International Paint & Coatings Exhibition take place?It is held annually in autumn at Tehran International Permanent Fairground. Who can participate in the exhibition?Manufacturers of paints, resins, industrial coatings, laboratory equipment, composite industries, engineering consultants, and industrial startups. What are the benefits of attending this exhibition?Direct connections with industry players, boosting sales and exports, discovering cutting-edge technologies, and learning about cost reduction strategies.

۳ آذر ۱۴۰۳

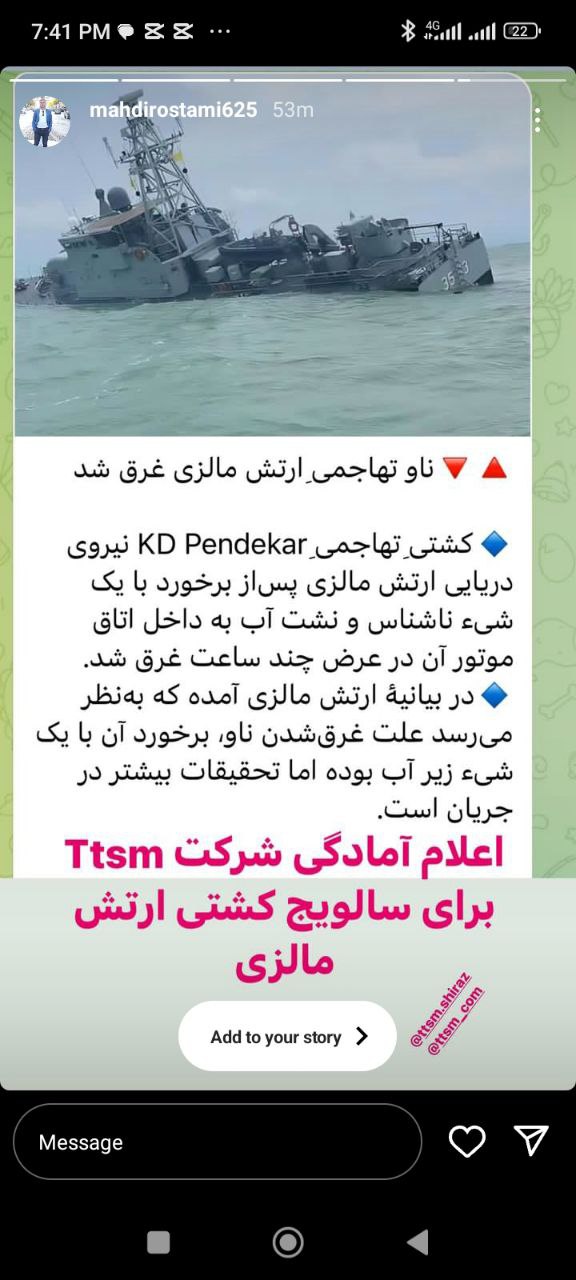

Malaysian Navy Warship KD Pend...

Malaysian Navy Warship KD Pendekar Sinks – TTSM Offers Salvage Operation The Malaysian Navy’s warship KD Pendekar sank just hours after colliding with an unidentified underwater object, which caused severe flooding inside its engine room. According to an official statement by the Malaysian Armed Forces, the cause of the sinking appears to be linked to the collision, although further investigations are underway. This incident has drawn major regional and international attention, as KD Pendekar was considered one of the key assault vessels of the Malaysian Navy. Its loss could significantly impact Malaysia’s naval operational capabilities. TTSM’s Role in Salvage Operations Following the sinking, TTSM, a leading company in ship salvage and recovery services, officially announced its readiness to support the operation. With years of expertise in salvage operations for naval, commercial, and tanker vessels, TTSM.co has proven capabilities in recovering sunken ships using advanced technology and highly skilled teams. TTSM’s management emphasized that the company is fully prepared to deploy modern salvage equipment and professional teams to assist in recovering the KD Pendekar. Importance of Salvaging KD Pendekar The salvage of a sunken warship is not only a matter of national security but also crucial to preventing marine environmental hazards and recovering sensitive military equipment. Given its track record, the Malaysian Armed Forces are expected to benefit from cooperation with specialized companies like TTSM.co to ensure a successful recovery mission. Conclusion The sinking of KD Pendekar marks a critical moment for the Malaysian Navy. In such circumstances, companies like TTSM play a key role in crisis management and restoring naval capabilities. For more information about TTSM’s specialized salvage services, visit the official website at TTSM.co

۱۰ شهریور ۱۴۰۳